MASSIVE Trussbilt Expansion Build: A Case Study

Trussbilt's warehouse expansion wrapped up in early summer 2021. Raeco Builders was excited to be part of this enormous undertaking. Below we have some fun facts about the project and what it took to get this done.

A Brief History

Trussbilt started in 1926 in Minneapolis and in 1989 moved to Huron, South Dakota. In 2019, Trussbilt decided to begin manufacturing modular cell systems; a fully enclosed cell. Trussbilt manufactures products and assembles them onsite. The finished product is a modular cell system they can send out to a job site for installation.

Project Goals

Mark Harvey from Trussbilt stated, “As we began to manufacture this new product, we realized we had many space restraints; even with a 100,000 square foot building, most of the space was currently in use, so we knew we needed to expand.”

In September 2019, Trussbilt contacted Raeco Builders to discuss ideas on how to build an expansion. “Initially, we looked at expanding the existing building to 215 feet, which would add around 50,000 square feet. However, after pricing and reviewing our goals and needs, we realized we needed closer to 100,000 feet to make this expansion worthwhile,” stated Mark Harvey.

Trussbilt went back to Tom Jurgens and Raeco to share the updated goals, and Raeco went to work to figure out how to get this done. Raeco presented the idea of creating a new building and connecting it to the existing building, instead of expanding on the old structure. This alternative building proposal allowed for the new larger building and would utilize Trussbilt's land to the fullest potential.

No one else had brought this idea to the table. Raeco Builders was selected as the general contractor on the project, and ground broke in 2020.

"We (Trussbilt) were super happy with the solution Tom and Raeco delivered, not only meeting our building size goals but also maximizing the footprint on our property. We have fully utilized the 12 acres of land, and our entire operation is under one roof," stated Mark Harvey.

Unique Project Challenges

The existing Trussbilt plant was built in 1977 and had already been added on to several times before. This presented some building permit challenges. Changes were needed to meet the new code, adding fire sprinklers and fire separations to address code and life safety. On top of that, the building size was essentially doubling. Furthermore, the manufacturing of cells was still ongoing, during construction, so managing equipment, materials, and more required lots of communication and teamwork.

The Conference Room and Additional Offices

Raeco built out an executive conference room and additional offices to help meet goals Trussbilt had as they grow. The new conference room is where Trussbilt spends a lot of time with their existing and prospective clients. It was essential to have a quiet, comfortable room to meet, and showcase the manufacturing floor without having to go onto the manufacturing floor. Raeco accomplished these goals by designing a large room with big one-way glass windows overlooking manufacturing and assembly floors. Trussbilt can now give clients an overall grasp on what goes into making and assembling these modular units.

Communication and Results

This was a great and actually, a pretty fun project; challenges included. One thing that helped make this work was the level of communication and transparency that Trussbilt and Raeco created.

To date, the most significant thing Trussbilt had done was relocate the facility from Minneapolis to Huron. On top of that, they started this project as Covid-19 was hitting. “People thought we were insane to take this on. We didn't have a choice. We needed the space and needed to launch our new product,” stated Mark Harvey.

"It's gonna be fantastic and could not have happened without a lot of teamwork from both sides." Mark Harvey, COO Trussbilt

Trussbilt in Huron, South Dakota Project Highlights:

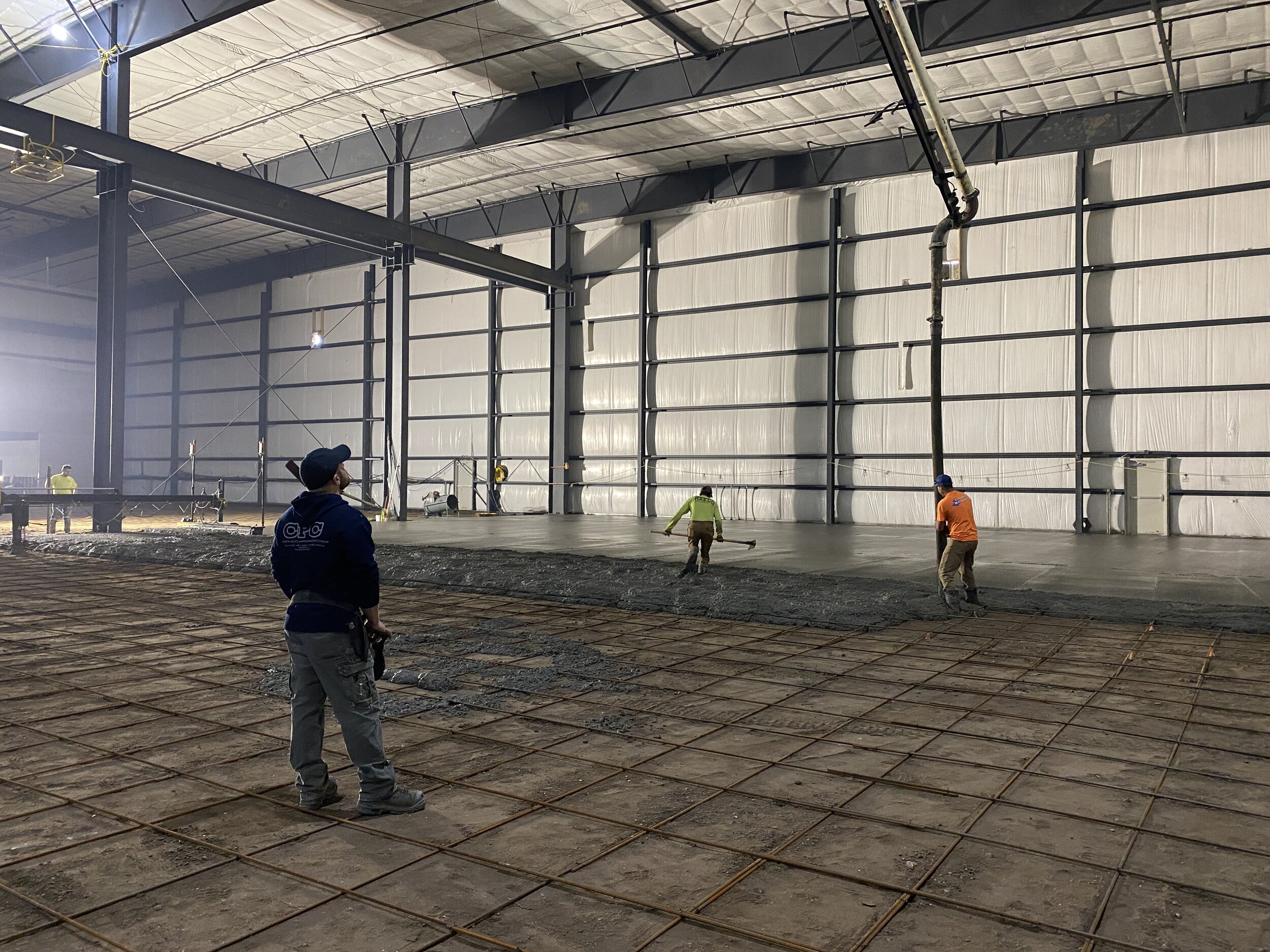

100,000 square foot warehouse building with connection to an existing facility.

Unique building placement allowed for full use of 12 acres of land

Overcame challenges as Covid-19 hit and as Huron was a national hotspot

In addition to the large warehouse, a receiving bay for the raw product (steel) was constructed on the east side of the existing building.

Thicker concrete bases added for new laser breaks

Added new executive conference room with windows overlooking manufacturing floor and assembly area

The siding was redone to make additions match for a seamless look

25-foot interim space was added between the old plant and new building to account for the new height and for snow load as well as firewall separation.

Fire protection room and sprinklers added with over five miles of piping

Installed two 106 Foot 5-ton cranes that can travel the length of the building. They are used to pick up cube cells and to load them onto a shipping truck.

A truck can pull into the building to load and get out of the weather. A big deal in South Dakota winters.

Simple saver fabric used as insulation retention and fire barrier.

----

If you are looking for some out-of-the-box thinking and want to build with the flexibility of metal framing without the "machine shed" design, look no further than RAECO Builders. We have the team and experience to bring your project to reality. We offer free initial consultations and would love an opportunity to earn your business. Contact us today.